Blog

Facility BMPs: We need your review!

New York State’s golf course BMPs were first published in 2014. Now five years later, we are updating the BMPs, in some cases adding new and updated information, including incorporating the pollinator BMPs (published in 2017). We have also incorporated discrete BMP statements to complement the BMP principles we identified in the first edition.

The draft final version of the Facility BMPs is available for download here: NYS_FacilityBMP_DraftFinal_05222019

To provide comments, please download the comment form here:

NYS Facility BMP_DraftFinalReview_CommentsForm

As part of the process of revising and updating, we are seeking input from superintendents across the state and the state’s regulatory agencies to review the draft final version and provide comments to NYGCF. Any superintendent or asst. superintendent in NYS is invited to participate in the review process. Superintendent reviewers should consider the content at three levels: the overall document, chapters, and page-by-page. The following are a few questions you may want to consider when reviewing:

- Are these BMPs something that can be implemented at your facility? How about facilities of varying sizes/budgets?

- Are there any topics that have not been covered in this document that you think should be addressed?

- Are there any topics that are covered, but may need additional detail?

- Is there any information presented that you think needs clarification?

Written comments submitted on or before July 16th to our project manager using the comment spreadsheet to submit comments. Please note: there are two pages in the spreadsheet – one each for specific comments and one for chapter comments. The superintendents on the NYGCF board and Cornell University scientists will review each comment and document how each comment is addressed in the final version.

NYGCF has undertaken the effort to create a facility BMP template to further implement BMPs across the state and to provide superintendents a process to make this process easy. Besides contributing to natural resources stewardship, additional incentives for golf courses in New York State to create a facility BMP plan and implement BMPs include the following:

- potential for more efficiently allocating resources by identifying management zones

- cost savings associated with applying less fertilizer and pesticide

- cost savings associated with more efficient irrigation and other water conservation efforts

- improving stormwater management efforts as storms in the area become more intense

- improved community relations`

- recognition by club members and the community at large as environmental stewards

We look forward to the input of superintendents across the state in this effort.

Lower DU Can Lead to More Uniform Soil Moisture

The golfing season in northern climates includes managing cool-season turf playing surfaces through stressful summer months (e.g. high temperature, low moisture). To prepare for summer stress, use opportunities in the spring during dry periods to apply strategic moisture stress to your playing surfaces by purposefully withholding water from the plant. Allowing soils to dry and create stress in this way often results in increased rooting and improved drought stress tolerance that will pay off in the summer.

The golfing season in northern climates includes managing cool-season turf playing surfaces through stressful summer months (e.g. high temperature, low moisture). To prepare for summer stress, use opportunities in the spring during dry periods to apply strategic moisture stress to your playing surfaces by purposefully withholding water from the plant. Allowing soils to dry and create stress in this way often results in increased rooting and improved drought stress tolerance that will pay off in the summer.

In addition, you should assess your irrigation system’s ability to produce uniform soil moisture before summer stresses occur. The application of supplemental irrigation water to maintain uniform soil moisture is critical for maximum playability and stress tolerance during dry periods. Increased accuracy in applying water through a well-designed in-ground irrigation system also allows for significant water conservation. These concepts are promoted in the following two BMP statements:

- Design and maintain irrigation systems to uniformly apply water to the intended area of management.

- Assess system efficiency through regular audits of application rate and uniformity.

However, the application efficiency of an irrigation system, measured as Distribution Uniformity (DU), may not always be the most effective measurement of system application that results in uniform soil moisture. This is especially true for undulating surfaces, with higher elevations often too dry and lower elevations too wet.

Applied water sheds rapidly, internally and externally, in a progressive fashion from higher elevations, and along the surface, down to the lower elevations. Research investigating sloped greens conducted at Michigan State University suggests building variable soil profile depths to address the uniquely inconsistent water holding properties found on sloped terrain when constructing new putting surfaces. This will insure shallower depth of rootzone profiles in the higher elevations that will hold more water and deeper rootzone profiles in the low areas to expedite drainage.

The only option to address the disparity in soil moisture on existing undulating surfaces, when adding drainage is not an option, is to alter the DU. In fact, research from the University of Wisconsin-Madison has demonstrated that irrigating a putting surface with a one percent slope required a change in DU from 80 percent to 17 percent to apply the correct amount of water for uniform soil moisture as measured by a time-domain reflectometer (TDR) probe (Spectrum 300).

Therefore, the BEST irrigation practice includes measuring soil moisture to assess system uniformity—not traditional catch-can tests. This will insure that plants have the moisture they need to provide firm playing conditions.

Managing Surface Organic Matter

Golf turf playability and performance lies at the heart of golf course Best Management Practices that protect and preserve water quality. Optimizing playability demands a well-drained, firm playing surface able to withstand traffic and demonstrate resiliency during normal play. The key to achieving these goals lies in the management of surface organic matter.

Turf is a perennial plant system that increases surface organic matter as a result of turf growth and management (Figure 1). Organic matter accumulates at the surface from the development and deposition of plant parts such as leaves, stems, and roots. Underground plant parts, such as stems (rhizomes) and roots, cycle as living, dead, and decomposing organic matter.

The accumulation of organic matter in the top 3 to 6 inches of a turf system increases over time and provides nutrients and water holding capacity, as well as Increasing the resiliency and traffic tolerance required of playing surfaces. However, when too much organic matter accumulates at the surface, it can restrict infiltration of water and when wet does not dry easily into a playable surface. This can reduce the effectiveness of fertilizer and pesticides and increase runoff volumes from the turf surface. The following NYS BMP statement is based on this premise:

Manage the surface accumulation of organic matter to maintain a permeable system that minimizes runoff and maximizes subsurface retention.

Turfgrass species, fertilization, and soil properties influence turf growth and organic matter accumulation. Assuming proper growth is maintained, organic matter accumulation in grasses could be managed through less invasive cultivation and light applications of sand throughout the season. A light application (0.1 to 0.2 inches) of material applied and integrated into the surface of the turf dilutes the organic matter and creates a physical matrix that functions as a soil.

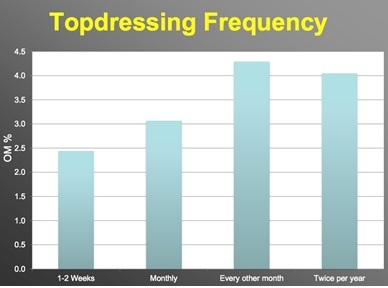

Topdressing is often performed in conjunction with some form of cultivation that simply makes a hole. Research at the University of Nebraska by Professor Roch Gaussoin shows clearly that topdressing frequency (even when compared to use with cultivation) had the greatest influence on organic matter accumulation. (Figure 2). Less invasive cultivation with solid tines provides minor disruption to create space for topdressing to serve the purpose of dilution and creation of a pseudo-soil matrix. Some research suggests the amount of topdressing sand that might be needed over a growing season increases. However, many opportunities to reduce organic matter accumulation exist via more precise N applications and more regular use of plant growth regulators. Ultimately, the goal of proper dilution is to ensure adequate infiltration while preserving sufficient retention of the turf system to prevent leaching.

To summarize the good, better best practices for managing organic matter accumulation are as follows:

- A good organic matter management program utilizes a calendar-based approach to N fertilization and plant growth regulator use and maintains a light/frequent topdressing program in combination with some form of cultivation.

- A better organic matter management program casually monitors turf growth rate, applies N based on growth potential (demand driven), applies plant growth regulators on a regular basis, and maintains a light/frequent topdressing program with less invasive cultivation applied during the season.

- A best organic matter management program measures clipping volume through the season, applies N based on growth potential (demand driven), applies growth regulators on a growing degree day formula, and strives to apply topdressing at a rate that carefully matches growth, finally utilizing cultivation to maintain surface infiltration.

Do You Get My Drift?

Drift when it comes to pesticide applications is something to be avoided, as it can potentially cause not only water quality impacts, but also damage to susceptible off target crops. In addition, a lower than intended rate of pesticide will be applied to the turfgrass, thus reducing its effectiveness. To avoid drift, the first step is to know the difference between types: airborne (spray) drift and vapor drift.

Drift when it comes to pesticide applications is something to be avoided, as it can potentially cause not only water quality impacts, but also damage to susceptible off target crops. In addition, a lower than intended rate of pesticide will be applied to the turfgrass, thus reducing its effectiveness. To avoid drift, the first step is to know the difference between types: airborne (spray) drift and vapor drift.

Spray Drift

The U.S. Environmental Protection Agency defines pesticide spray or dust drift as “the physical movement of pesticide droplets or particles through the air at the time of pesticide application or soon thereafter from the target site to any non- or off-target site”. Spray drift is influenced by many inter-related factors including droplet size, nozzle type and size, sprayer design, weather conditions and the operator.

Droplet Size

Lower spray volumes can result in smaller droplets that enhance leaf coverage although there is a limit to droplet size due to drift. Droplets under 150 microns generally pose the greatest hazard; droplets less than 50 microns have insufficient momentum for impaction as they remain suspended in the air indefinitely or until they evaporate. The higher the operating pressure, the smaller the droplet. Conversely, low pressure produces large droplets that may bounce off the target. Certain spray surfactants can change the droplet spectrum, reducing the number of driftable droplets.

Nozzle Type and Size

Correct nozzle selection is one of the most important, yet inexpensive, aspects of pesticide application. A nozzle’s droplet size spectrum determines deposition and drift. Conventional flat fan nozzles fitted to a turfgrass sprayer produces droplets in the range of 10 – 450 microns. (Note: 25,000 microns = 1 inch.) Drift is a concern with droplets less than 100 microns. Increasing the Volume Median Diameter (VMD) reduces drift, but droplets that are too large bounce off the leaves to the ground.

Sprayer Design

Shields are better at targeting the spray into the grass, reducing drift and increasing deposition. They vary from the simple to the complex. Shielded sprayers allow managers to apply pesticides in variable weather conditions.

Weather Conditions

Wind speed and direction, relative humidity, temperature and atmospheric stability affects drift.

Calibration

Correct sprayer calibration ensures that all the nozzles are discharging the correct amount of liquid at the correct distance and angle to the target and at the correct forward speed.

Vapor Drift

Vapor drift is caused by pesticide volatilization – the chemical process whereby pesticide surface residues change from a solid or liquid to a gas or vapor after application. Once airborne, volatile pesticides may drift off site. Pesticide volatility varies, and not all pesticides volatilize.

The amount of vapor drift depends upon a pesticide’s volatility and atmospheric conditions such as humidity, temperature. Turfgrass pesticides with known volatility should be avoided. In some cases, the pesticide label may indicate low volatility. However, low volatility does not mean that a chemical will not volatilize under conducive conditions, such as high temperatures or low relative humidity.

Best Practices for Spraying

Before spraying:

- Train the operator to use the sprayer correctly.

- Plan the spraying operation; consider the use of spray instruction cards as a good management tool.

- Read and follow the pesticide label.

- Select the correct nozzle for the target. Adjust the size and position of the nozzles to achieve correct distribution within the grass canopy.

- Consider the use of sprayer nozzles which direct the spray to the target.

- Consider spray additives to reduce drift.

- Improve spraying logistics to ensure adequate time to spray within ‘ideal’ conditions.

- Only spray when weather conditions are ideal; avoid spraying on days when conditions are favorable for atmospheric inversion or wind drift.

- Calibrate the sprayer with water to ensure that everything is working correctly.

During spraying:

- Stay alert: ensure the spray is not allowed to drift on to non-target areas and watch for changes in wind speed and direction.

- Keep spray pressure as low as possible and ensure an accurate gauge is used.

- Maintain a constant speed and pressure. If an automatic regulator is fitted, remember, small increases in speed result in large increases in pressure.

- Avoid spraying near sensitive crops or watercourses; use a buffer zone.

You Can Help Monarchs

Most people can easily recognize a monarch butterfly, but did you know that their numbers have suffered dramatic declines in the last 40 years? Habitat loss in both their summer and overwintering locations has played a major role in this decline.

Monarch butterflies only lay their eggs on milkweed and their caterpillars only eat milkweed. Therefore, superintendents can allow milkweed to persist in open areas and can introduce milkweed into suitable areas on the course if none currently exists.

A new program aimed specifically at helping superintendents to conserve monarch habitat can provide assistance in these efforts. Monarchs in the Rough, sponsored by Audubon International and the Environmental Defense Fund, provides superintendents with regionally appropriate milkweed seeds to restore monarch butterfly habitat in out-of-play areas. Monarchs in the Rough also offers signage, posters, and technical guidance to golf course managers in the installation and management of monarch habitat and ideas of how to communicate with course members about these conservation efforts.

A Foundation for Sustainability: The New York Golf Course Foundation

The New York Golf Course Foundation (NYGCF) is a newly launched non profit to promote sustainable golf management efforts in New York State. This new organization is an evolutionary step for the New York State Best Management Practices (BMPs) project begun in 2012 that established the state’s first golf industry BMPs.

The foundation’s mission is to continue and expand upon the work of the BMP committee, raise the profile of the state’s golf industry with respect to its environmental sustainability efforts, and to fundraise to provide a sustainable source of revenue to continue these efforts. Scientists from Cornell University will continue working with NYGCF to update the BMPs, address new topics as the need arises, and provide education to the superintendent target audience.

The current focus of the NYGCF is outreach and education aimed at promoting the acceptance and implementation of BMPs by the state’s golf course superintendents. In addition, the Foundation will continue to promote the recognition of BMPs as the best way to protect and preserve our water resources and enhance open space. State lawmakers and regulators have applauded our past efforts and the Foundation’s directors will continue to inform these key stakeholders of the activities of the new Foundation.

Under a current Turf Environmental Stewardship Foundation (TESF) grant, the foundation is working on an update to the state’s BMPs that will be incorporated into a template that can be used by any superintendent in the state to create a site-specific facility BMP. Once completed, the foundation will provide information and workshops for superintendents to become more familiar with the process of completing their own BMP document. Taking the time to create a facility BMP can pay off in a number ways; for example, superintendents can use their site-specific BMP document as a resource during the permit negotiating process with local towns by recognizing the club’s commitment to protecting water quality or as a tool to educate golfers and/or the interested non-golfing public regarding the industry’s commitment to environmental stewardship. The facility BMP tool is expected to be available to superintendents through the GCSAA’s BMP portal by October.

In addition to the facility BMP template development, the Foundation is currently working on re-establishing its Twitter feed (@NYS_GolfBMP), publishing new blogs on the website, and documenting case studies of BMP implementation. The Twitter feed, blogs, and case studies are designed to inform, update, and educate superintendents about time sensitive BMP-related methods for completing various environmentally sensitive tasks. The NYGCF will also continue maintaining and updating the BMP website (https://nygcf.com/nysgolfbmp_com/).

We invite superintendents to subscribe to the Twitter feed, submit case studies (through the website comment field), and read our blog.

No Kidding: Using Goats to Control Vegetation

At Whippoorwill Club in Armonk, buffer strips around ponds on the property had become overgrown and encroached upon by invasive species. Because of the rocky, steep hillside, chemical control was not an option and physical removal difficult.

To control the growth, an innovative approach to vegetation removal was utilized: goats. Goats are browsers who prefer brushy vegetation and vines (including poison ivy) versus other species like sheep who prefer to graze on grass. Goats are also unique in weed seeds are left unviable after being digested and will not grow out of their excrement. Green Goats, a company out of Rhinebeck NY, was used to introduce goats and set up fencing. Three foot livestock fencing powered by a solar powered fence charger was used to enclose the area for the goats.

The project was very successful and areas that were completely overgrown were cleared of foliage within a couple of weeks. It also provided a significant cost savings – estimated at $15,000 less than what would have been spent to remove the overgrowth physically. In addition, because of the conservation easement on the property, goats were the only viable option for clearing the overgrown areas. The area cleared by the goats will be replanted with native species.

Because of the project’s success, goats will be brought back to new areas. Though very successful, the goats did have one unintended side effect: they slowed play. As members passed the area, many would stop to see the goats and take pictures.

What’s In Your Spill Kit?

Spills happen and being prepared can make the difference between being able to safely contain the spill and not. Have you checked your spill kit recently to make sure you have everything you may need? The following is a checklist for what should be in your spill kit at a minimum to make sure a small issue does not become a bigger problem:

- Gloves (nitrile, at least; foil barrier laminate better)

- Tyvek® coverall

- Goggles

- Temporary storage container for spill

- Sorbent pads and/or socks

- Loose absorbent (SlikWik®, vermiculite)

- Sweeping compound

- Warning sign or caution tape

- Chalk (for marking spill area on floor)

- Dust pan or small shovel (plastic preferable)

- Small broom

- Permanent marker (for marking spill container after clean-up)

Forms of Sorbents

- Booms: cylindrical shape; vary in length and width; used to control and contain spills

- Socks or mini booms: cylindrical shape; vary in length and width; used in facility spill response or maintenance; contain spills or leaks (placed around equipment)

- Pillows: rectangular in shape; used for medium size spills; can be used for leaks and drips

- Pad and rolls: flat sorbent sheets of various lengths can be used to line shelves, catch leaks under machinery and clean up spills

- Loose sorbents: sorbent media that is not contained in any type of pillow or mesh; typically used on small spills

Sorbent Categories

- Universal sorbents: designed to absorb any liquid; they will absorb aggressive liquids such as acids and bases as well as non-aggressive liquids and solvents, such as cleaners, water-based fluids, gasoline and alcohol; made of polypropylene or expanded silicate materials.

- Petroleum sorbents (“oil-only sorbents”): designed for absorption of oil and/or petroleum-based liquids; these sorbents are hydrophobic (will not absorb water or water-based liquids); can be used in maintenance applications for hydraulic and engine oil cleanup; made of polypropylene or treated cellulose.

- Maintenance sorbents: absorb non-aggressive liquids commonly found in manufacturing and maintenance operations (coolants, lubricants, oils, cutting fluids) will pick up water-based as well as oil-based fluids; made of recycled materials, such as cotton, wool, cellulose or corn cob; can also be made of polypropylene or any combination of the materials listed.

Sorbent capacity: The amount of weight the sorbent will absorb in relation to itself (e.g., absorbs 12 times its weight) or the liquid capacity of the sorbent (e.g., absorbs 8 gallons). Because all liquids don’t weigh the same per gallon, the weight capacity of the sorbent actually varies from liquid to liquid. A more accurate way to assess the sorbent capacity is by its liquid capacity.

For more information and suppliers, see Cornell’s Occupation & Environmental Health Department’s Recommendations – Pesticide Spill Kit Contents.

It’s Spring! Time to Plan for Pollinators

Spring is a great time to consider adding native plants to your facility to create additional habitat for pollinators and review the availability of nesting sites for these species.

Pollinator habitat on the golf course includes both areas planted specifically with pollinators in mind and existing out-of-play areas. One of the most effective BMPs for protecting water quality also protects pollinator habitat, i.e., leaving a low- or no-management buffer strip around water courses and bodies of water.

To add habitat for pollinators, add a diversity of blooming plants of different colors and heights that blossom throughout the entire growing season. Native plants are best, proving the most nutritious food source for native pollinators. Even plants we consider weeds provide important habitat. For example, milkweed is a food source for monarch caterpillars. Monarchs in the Rough, a program sponsored by Audubon International and the Environmental Defense Fund, can provide you with regionally appropriate milkweed seeds to restore monarch butterfly habitat in out-of-play areas.

In addition to food, pollinators need places to nest. Simple efforts can increase nesting sites, such as leaving stems and coarse, woody debris and leaving exposed patches of well-drained soil, or by creating nesting areas such as wooden nesting boxes for hole nesting bees.

For more information on nest site plans and native plants species for pollinators see:

- Making Room for Native Pollinators, Matthew Shepherd.

- Host plants for specialist bees of the Mid-Atlantic and Northeastern United States, Jarrod Fowler. Recommendations regarding pollinator plants, native plant nurseries and seed companies, conservation guides, and policies.

Best Management Practices

- Utilize native species when renovating out-of-play areas.

- Choose flowers of different shapes, sizes, and colors.

- Choose species that bloom at different times of the year.

- Include both perennials and annuals in native plant areas.

- Choose south-facing sites whenever possible for establishing native areas.

- Leave stems and coarse, woody debris in native areas for pollinator nesting.

- Leave exposed patches of well-drained soil in native areas for pollinator nesting.

- Consider joining the Monarchs in the Rough project.

- Provide water sources with shallow sides to prevent pollinators from drowning.

Educational Plan

Since publishing the Best Management Practices for NYS Golf Courses book and this website, the NYS BMP committee has focused on outreach and education efforts to promote the acceptance and implementation of BMPs in New York State’s golf industry.

Since publishing the Best Management Practices for NYS Golf Courses book and this website, the NYS BMP committee has focused on outreach and education efforts to promote the acceptance and implementation of BMPs in New York State’s golf industry.

As part of these efforts, the committee surveyed the state’s golf course professionals to conduct a formative assessment of BMP concepts and a survey of BMPs as implemented on NYS golf courses. This survey was conducted in 2015 and early 2016 with a response window of four months. Once the survey period ended, the results were analyzed to determine educational and outreach priorities for our target audience of NYS superintendents and assistant superintendents. The following topics were identified to emphasize and prioritize:

- pesticide and fertilizer storage and handling

- pesticide and fertilizer application

- regulations such as the P-law

- key elements of a progressive golf turf IPM program

- equipment washing areas

- optimizing irrigation systems

- soil nutrient test interpretation

To find out more on the quiz and survey results and how the NYS BMP committee is implementing the plan, download the Educational Plan (pdf).